-

GeorgeThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

GeorgeThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

AlexandraGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

AlexandraGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package. -

ElaneThrough very good communication all problems solved, satisfied with my purchase.

ElaneThrough very good communication all problems solved, satisfied with my purchase.

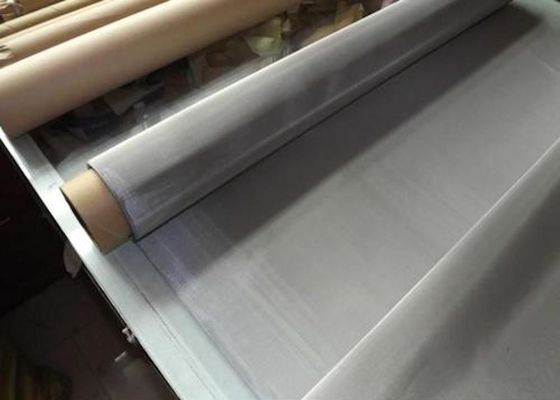

High Tension Filtration 1m Stainless Wire Mesh Screen

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Stainless Steel Screen Mesh | Mesh | 1 - 600 Mesh |

|---|---|---|---|

| Material | Stainless Steel 201, 304, 304L, 316, 316L | Wire Diameter | 2 - 0.018mm |

| Length | 30m/roll 50m/roll Or As Required | Mesh Opening | 0.025-23.37mm |

| Weave Type | Plain / Twill / Dutch / Dense Weave | Color | Customized |

| Usage | Filter, Screen Prinitng, Printing And Dyeing | Sample | Small Sample Free |

| We Are Factory | Low MOQ, Lowest Price And The Best Service | Packing | Paper Tube Inside + Waterproof Paper/plastic Bag + Wodden Box/pallet |

| Highlight | 1m Stainless Steel Screen Mesh longkuo,0.018mm stainless wire mesh screen longkuo,Filtration Stainless Steel Screen Mesh |

||

Width Usually 1m or others High Tension Filtration Stainless Steel Screen Mesh

Product Information

Stainless Steel Screen Mesh refers to the regular arrangement of stainless steel products made of stainless steel wire or plate. Usually 200 mesh - 600 mesh is called high mesh stainless steel mesh, material: 201, 304, 304L, 316, 316L.

Advantage

1. Good acid, alkali and corrosion resistance;

2. High strength, strong tensile force, toughness and wear resistance, durable;

3. It is resistant to high temperature oxidation, and the nominal temperature of 304 stainless steel screen is 800 ℃;

4. Normal temperature processing, that is, easy plastic processing, makes the possibility of using stainless steel screen diversified;

5. High finish, no surface treatment, easy maintenance.

Technology

1. Plain weave:

Plain weave is a knitting method in which each warp crosses each weft, the diameter of which is the same as weft, and the warp and weft form a 90 degree angle. Plain woven mesh is square and uniform in size. Each warp is crossed up and down each weft, the diameter of the warp is the same as the weft, and the warp and weft form a 90 degree angle.

2. Twill weave:

The knitting mode in which each warp thread crosses each two weft threads and each weft thread crosses each two diameter threads.

3. Dense weave:

Warp and weft yarns have different diameters and mesh numbers. They are characterized by thin warp and dense weft, thick warp and thin weft. The direction of length is warp and the direction of width is weft. Dense mesh is divided into plain weave and twill weave.

4. Mat net twill knitting:

The knitting mode in which each diameter filament crosses up and down every two weft yarns, and each weft filament crosses up and down every two diameter yarns.

5. Double wire Dutch knitting:

This kind of knitting is very similar to twill Dutch knitting. There are two weft threads, which can be closely overlapped with the warp. This kind of silk cloth is mostly used for micron level filtration.

Company Introduction

We are one of the largest manufacturers of stainless steel wire mesh in China. It is a chemical plant integrating production, sales, wholesale and retail. All products are provided with one-stop service. From wire drawing, mesh weaving, deep processing and inspection, we operate independently. All materials, sizes and specifications can be customized according to customer requirements.

Material composition table

| AISI Material |

Chemical omposition(%) | |||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Ti | |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.06 | ≤0.03 | 3.5~5.5 | 16~18 | - | - | |

| 304 | <0.08 | <1.0 | <2.0 | <0.035 | <0.03 | 8~10 | 17~19 | - | - | - |

| 304L | <0.03 | <1.0 | <2.0 | <0.04 | <0.03 | 9~13 | 18~20 | - | - | - |

| 316 | <0.08 | <1.0 | <2.0 | <0.04 | <0.03 | 10~14 | 16~18 | 2.0~3.0 | - | - |

| 316L | <0.03 | <1.0 | <2.0 | <0.04 | <0.03 | 12~15 | 16~18 | 2.0~3.0 | - | |

Product specification parameter table

|

Mesh |

Wire diameter mm |

Aperture mm |

Mesh |

Wire diameter mm |

Aperture mm |

|

| 2 | 1.80 | 10.90 | 90 | 0.11 | 0.172 | |

| 3 | 1.60 | 6.866 | 100 | 0.10 | 0.154 | |

| 4 | 1.20 | 5.15 | 120 | 0.08 | 0.132 | |

| 5 | 0.91 | 4.17 | 140 | 0.07 | 0.111 | |

| 6 | 0.80 | 3.433 | 150 | 0.065 | 0.104 | |

| 8 | 0.60 | 2.575 | 160 | 0.065 | 0.094 | |

| 10 | 0.55 | 1.99 | 180 | 0.053 | 0.088 | |

| 14 | 0.5 | 1.314 | 200 | 0.053 | 0.074 | |

| 18 | 0.45 | 0.961 | 250 | 0.04 | 0.061 | |

| 20 | 0.40 | 0.87 | 325 | 0.035 | 0.043 | |

| 30 | 0.305 | 0.542 | 350 | 0.033 | 0.0395 | |

| 50 | 0.20 | 0.308 | 400 | 0.03 | 0.0335 | |

| 60 | 0.19 | 0.223 | 500 | 0.025 | 0.0258 | |

| 70 | 0.14 | 0.223 | 600 | 0.018 | 0.023 | |

| 80 | 0.12 | 0.198 | ||||

![]()

![]()

![]()